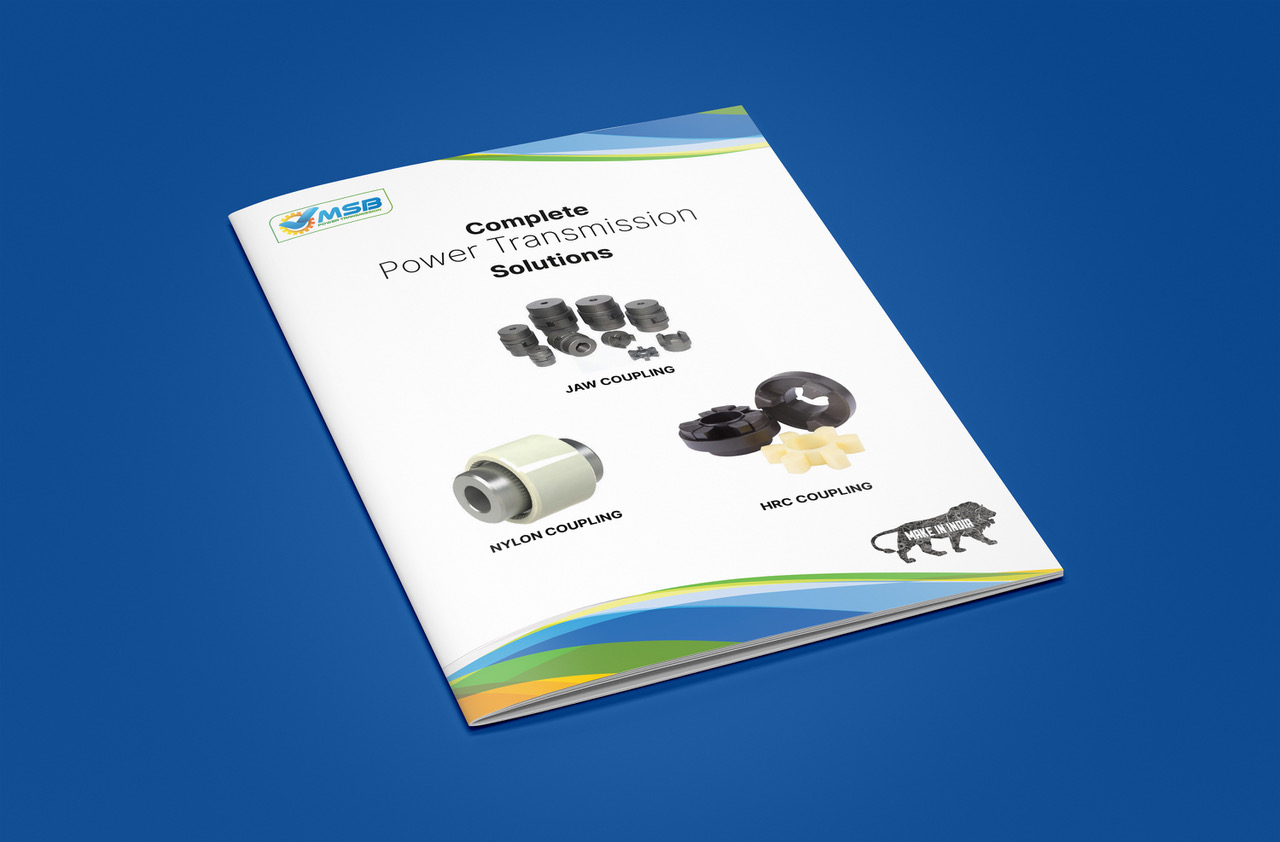

Jaw Coupling

Jaw Coupling

With its unique wrap around Nitrile rubber connecting element, the Snap Wrap coupling eliminates the need for dismantling the connected equipment while inspecting or replacing the element – a major benefit when down time on machinery can run into huge amounts.

Combined with a range of prebored hubs, a modular hub design and a spacer option, the Snap Wrap coupling is unsurpassed for quality, flexibility, speed of installation and maintenance.

Description

6 Ways the “Snap Wrap” coupling can help pay for itself:

1. Prebored hubs ubs bored and keyed to standard IEC motor shaft sizes.

2. Snap Wrap element Ease of inspection and replacement within 5 minutes.

3. Modular hub design Both Models, SW & RRS use the same hubs.

4. Spacer coupling RRS spacer model is available for pump applications

5. Fully machined hubs Balance, ease of alignment and smooth contact surface for elements are assured.

6. Any environment Water, oil, greases & dust do not affect performance.

SELECTION PROCEDURE

(a) Service Factor

Determine appropriate SERVICE FACTOR from table A.

(b) Design Power

Convert application rating at 100 rpm by multiplying service factor. This gives DESIGN POWER which is used as a base for coupling selection.

(c) Coupling Size

Refer respective table for your required coupling type and read from the appropriate speed column until a power equal to or greater than the DESIGN POWER is found.

(d) Bore Size

Refer respective coupling ‘TECHNICAL DATA’ table to check that the required bores can be accommodated.