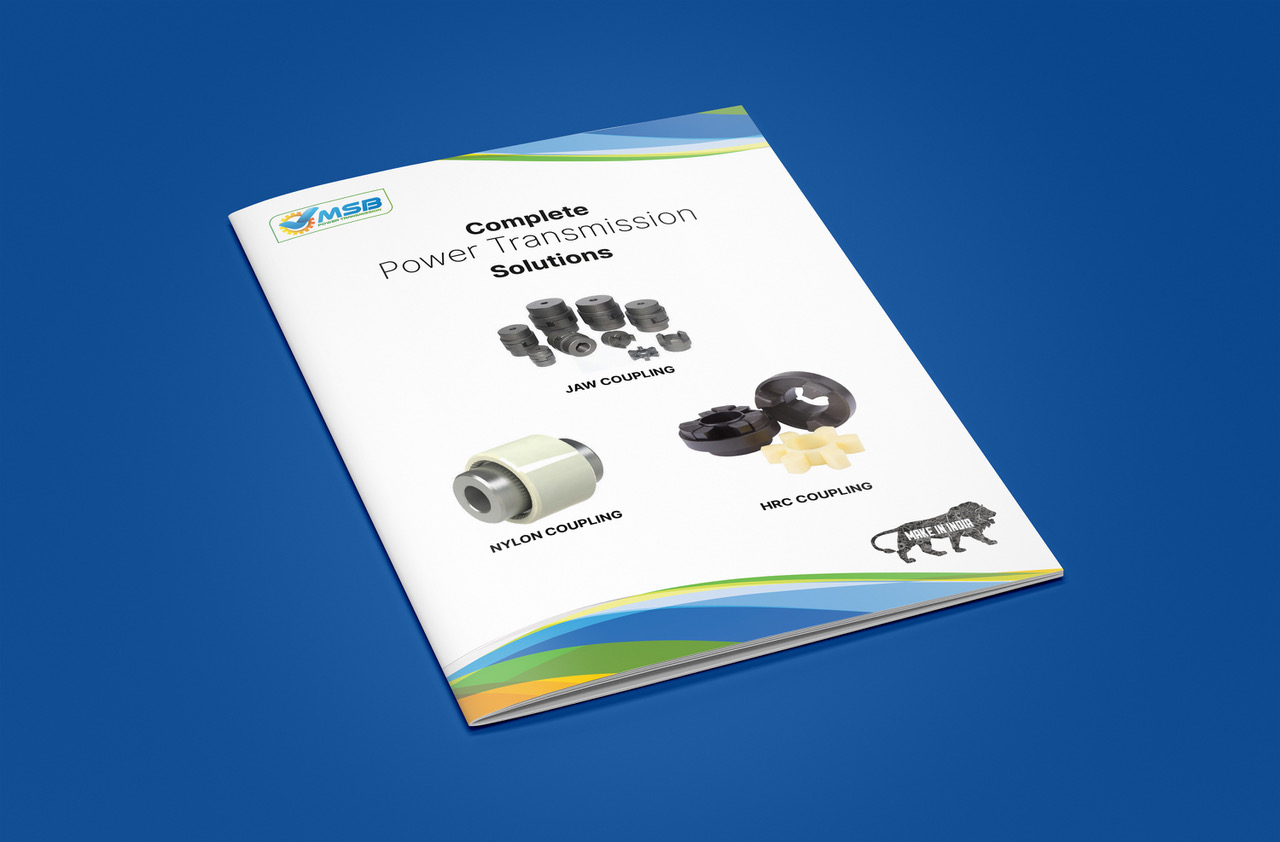

Jaw Coupling

Jaw Coupling

MSB India is a Jaw coupling, coupling jaw, Flexible jaw coupling manufacturer based in Mumbai India, specializing in accurate and high-performance couplings. Contact us today for your coupling needs.

Typical applications include power transmission for industrial equipment such as pumps, gearboxes, compressors, blowers, mixers, and conveyors. Lovejoy offers a range of designs and models in various sizes for the replacement couplings market. Their jaw-type couplings come in 24 sizes, with torque ratings from oz-in (Nm) to a maximum of 004,000 oz-in2 (19,209 Nm) and diameters up to 7 inches (178 mm). Lovejoy also provides standard bore options in AGMA, SAE, and DIN bore/keyway and spline combinations.

| Motor

Frame Size |

Shaft Dia. mm. | 3000 rev/min | 1500 rev/min | 1000 rev/min | 750 rev/min | |||||||

| Motor

Power kW |

Coupling Size | Motor

Power kW |

Coupling Size | Motor

Power kW |

Coupling Size | Motor

Power kW |

Couping Size | |||||

| 90 S | 24 | 1.5 | 70 | 1.1 | 70 | 0.75 | 70 | – | – | |||

| 90L | 24 | 2.2 | 70 | 1.5 | 70 | 1.1 | 70 | – | – | |||

| 112 M | 28 | 4 | 90 | 4 | 90 | 2.2 | 90 | – | – | |||

| 132 S | 38 | 5.5 | 110 A | 5.5 | 110 A | 3 | 110 A | 2.2 | 110 A | |||

| 7.5 | 110 A | |||||||||||

| 132 M | 38 | 7.5 | 110 A | 4 | 110 A | 3 | 110 A | |||||

| 5.5 | 110 A | |||||||||||

| 160 M | 42 | 11 | 110 A | 11 | 110 A | 7.5 | 110 A | 4 | 110 A | |||

| 15 | 110 A | 5.5 | 110 A | |||||||||

| 160 L | 42 | 18.5 | 110 A | 15 | 110 A | 11 | 130 | 7.5 | 110 A | |||

| 180 M | 48 | 22 | 150 | 18.5 | 150 | |||||||

| 180 L | 48 | 22 | 150 | 15 | 150 | 11 | 150 | |||||

| 200 L | 55 | 30 | 180 | |||||||||

| 37 | 180 | 22 | 180 | |||||||||

| 225 S | 60 | 37 | 180 | 18.5 | 180 | |||||||

| 225 M | 55 *

60 |

45 | 180 | 45 | 180 | 30 | 180 | 22 | 180 | |||

| 250 M | 60 *

65 |

55 | 180 | 55 | 230 | 37 | 230 | 30 | 230 | |||

| 280 S | 75 | 75 | 230 | 45 | 230 | 37 | 230 | |||||

| 280 M | 75 | 90 | 230 | 55 | 230 | 37 | 230 | |||||

| 315 S | 80 | 110 | 280 | 75 | 280 | 55 | 280 | |||||

| 315 M | 80 | 132 | 280 | 90 | 280 | 75 | 280 | |||||

| * 3000 rev/min only.

a. ServiceFactor DeterminetherequiredservicefactorfromTable1. b. DesignPower |

®Registered Trade Mark

Example : A shaft coupling is required to transmit 70kW between a 1440 rev/min electric motor and a hoist running over 16 hours/day. The motor shaft is 70 mm. and the hoist shaftis75mm. |

|||||||||||

Six Ways the Snap Wrap Coupling Can Help Pay for Itself:

- Pre-bored hubs: Bored and keyed to standard IEC motor shaft sizes.

- Snap Wrap element: Allows for inspection and replacement within 5 minutes.

- Modular hub design: Both models, SW and RRS, use the same hubs.

- Spacer coupling: The RRS spacer model is available for pump applications.

- Fully machined hubs: Ensures balance, ease of alignment, and a smooth contact surface for elements.

- Any environment: Water, oil, grease, and dust do not affect performance.

The Snap Wrap coupling, a type of flexible jaw coupling, is included in the jaw coupling catalogue. The coupling jaw design features a rubber jaw coupling element that provides durability and flexibility. Among the various jaw coupling types, the Snap Wrap is especially noteworthy for its innovative and efficient design.

SELECTION PROCEDURE

(a) Service Factor

Determine appropriate SERVICE FACTOR from table A.

(b) Design Power

Convert application rating at 100 rpm by multiplying service factor. This gives DESIGN POWER which is used as a base for coupling selection.

(c) Coupling Size

Refer respective table for your required coupling type and read from the appropriate speed column until a power equal to or greater than the DESIGN POWER is found.

(d) Bore Size

Refer respective coupling ‘TECHNICAL DATA’ table to check that the required bores can be accommodated.